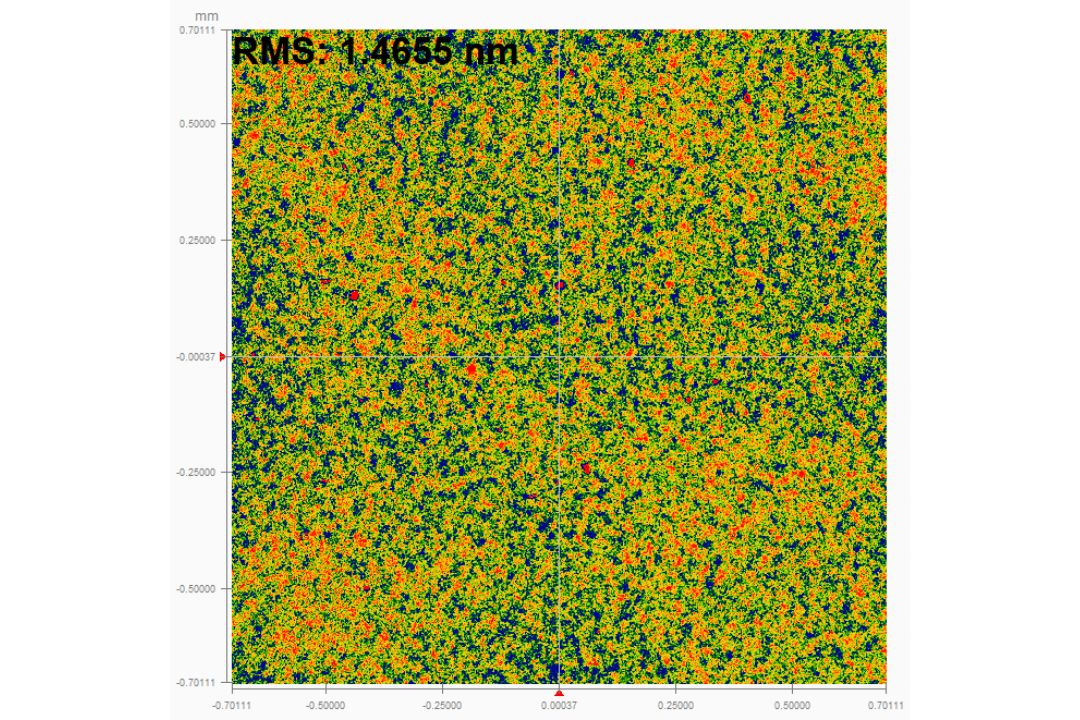

定時測量表面粗糙度能夠了解零件的使用情形,可快速判斷如何降低零件的耗損。測量和控管光罩基板和substrates的粗糙度可以在鍍膜的過程中表現出良好的附著程度以及光澤度。此外,測量鍍膜表面的粗糙度可得知鍍膜和拋光後其成品的性能。

4D 光學表面輪廓儀可以在不需隔絕振動的情況下,直接在生產現場測量表面粗糙度。NanoCam HD 能夠測量光滑和超光滑表面,可直接應用於拋光設備、龍門架、機器人或大型元件。

客戶定製方案將粗糙度測試融入軟性電子產品的捲對捲 (R2R) 製造,實現即時監控以及將粗糙度控制在小於0.5奈米rms的範圍之中。

Technical Resources

技術文件下載

Measuring Sub-Angstrom Roughness

How do you measure roughness with sub-angstrom precision in a noisy manufacting environment?

Read this white paper for a break-down of the options, and illustrations of the challenges present in different solutions.

Measuring MEMS and other vertical roughness surfaces

A new technique provides a faster, more repeatable method for vibration-insensitive measurement in non-ideal environments.

b Measuring Surface Features with High Resolution in Factory Environments

This article from Industrial Photonics magazine illustrates how the ability to measure surface defects and features anywhere in the factory or on the flightline can be a transformative change in quality control procedures.